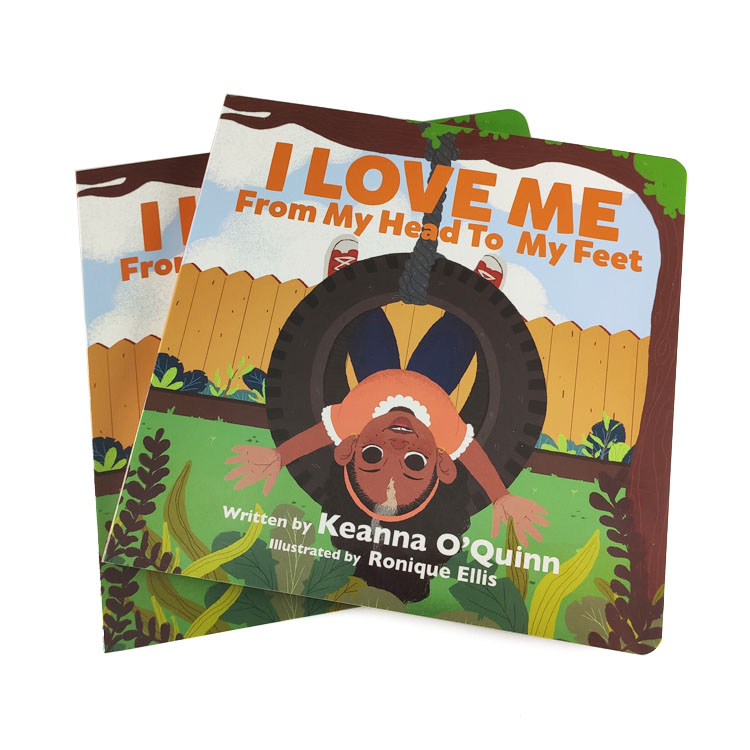

As a professional in the printing industry, I often get asked about the process of custom board book printing. Board books are a popular choice for children's books due to their durability and ability to withstand rough handling. In this article, I will walk you through the step-by-step process of custom board books printing using offset printing, as well as provide some tips for achieving high-quality results. So, let's dive in!

Steps of board book printing process

Board book printing involves several steps to ensure a well-crafted final product. Each step plays a crucial role in achieving the desired outcome. Let's take a closer look at the board book printing process.

1. CTP Plate making

The first step in board book printing is CTP (Computer-to-Plate) plate making. CTP technology allows for precise transfer of digital artwork onto printing plates. This step involves converting digital files into plates that will be used for the actual printing process. CTP plate making ensures accurate reproduction of colors and images, resulting in a high-quality board book.

2. Printing and color matching

Once the plates are ready, the next step is printing and color matching. Offset printing is commonly used for board book printing due to its ability to produce vibrant colors and sharp images. During this stage, the printing press applies ink to the plates, which are then transferred onto the board book pages. Color matching is crucial to ensure consistency and accuracy in reproducing the intended colors. Skillful technicians use color management systems to achieve the desired color fidelity.

3. Laminating

Laminating is an essential step in the board book printing process, as it adds an extra layer of protection to the pages. A thin laminate film is applied to the printed pages, providing durability and resistance to tearing or peeling. This protective layer also makes the board book more resistant to spills and stains, ensuring a longer lifespan for the book.

4. Die cutting

Die cutting is the process of cutting the board book pages into the desired shape. Custom board books often have unique shapes, such as rounded corners or cutouts or custom pop up books. Die cutting machines are used to precisely cut the pages according to the specified design. This step adds a personal touch to the board book, making it visually appealing and engaging for young readers.

5. Binding

Binding is the stage where the individual pages of the board book are combined to create a cohesive whole. There are different binding methods available for board books, including self-cover board book binding and hardcover board book binding. Self-cover board book binding involves two sheet of cardboard wrapped together and then self-cover to be a book. Hardcover board book binding involves two sheet of cardboard wrapped together and then glued on a thick hard cover to be a book. The choice of binding method depends on factors such as book thickness and intended use. Both binding ways are enough strong to withstand frequently read and tear off by little children.

6. Trimming

The final step in the board book printing process is trimming. Trimming ensures that all the pages of the board book are cut to the same size and have clean, professional edges. Precision trimming is essential to achieve a polished look and ensure that the board book opens and closes smoothly. This step adds the finishing touch to the custom board book, making it ready for distribution.

Above 6 steps are the main processes of making board books, pay attention to each step is very important to make sure in high quality printing result.

Tips for high quality board book printing

Now that we have covered the step-by-step process of custom board book printing, let's discuss some tips for achieving high-quality results:

Choose a reputable printing company: Look for a board book printer with experience in board book printing and a track record of delivering high-quality products. Check their portfolio and customer reviews to ensure their expertise in producing custom board books.

Use high-resolution images: To ensure sharp and clear images in your board book, use high-resolution images in your artwork. Low-resolution images may appear pixelated or blurry when printed, compromising the overall quality of the book.

Pay attention to color accuracy: Colors play a vital role in board book printing, especially when it comes to captivating young readers. Make sure to communicate your color preferences to the printing company and request color proofs before proceeding with the actual printing.

Consider the target audience: Keep the age group of your target audience in mind when designing the board book. Use appropriate fonts, illustrations, and content that resonate with the intended readers. Engaging and age-appropriate board books are more likely to be well-received.

Proofread and review: Before finalizing the artwork for printing, thoroughly proofread the content and review the layout. Check for any spelling or grammatical errors, as well as ensure that the design elements are properly aligned and visually appealing.

How to prepare artwork for printing

To ensure a smooth printing process and achieve the desired outcome, it is essential to prepare the artwork correctly. Here are some steps to follow when preparing artwork for board book printing:

Choose the right file format: Save your artwork in a high-resolution, print-ready file format such as PDF or TIFF. These formats preserve the quality of the images and ensure accurate reproduction during the printing process.

Set the correct bleed and trim marks: Include bleed and trim marks in your artwork to guide the printing company in trimming the board book pages accurately. Bleed allows for any slight variations in the trimming process, ensuring that the artwork extends beyond the actual page size.

Embed fonts and outline text: If you are using specific fonts in your artwork, make sure to embed them or outline the text. This ensures that the fonts appear correctly when the artwork is opened on different computers or printing systems.

Check image resolution: Ensure that all images in your artwork have a resolution of at least 300 DPI (dots per inch) to guarantee sharp and clear printing. Low-resolution images may result in pixelation or loss of detail.

By following these guidelines, you can ensure that your artwork is print-ready and optimized for custom board book printing.

In conclusion, custom board book printing with offset printing involves several steps, including CTP plate making, printing and color matching, laminating, die cutting, binding, and trimming. Each step contributes to the overall quality and durability of the board book. By following the tips provided and properly preparing the artwork, you can achieve high-quality custom board books that captivate young readers and withstand the test of time. So, if you are planning to print custom board books, make sure to choose a reliable printing company with expertise in board book printing and bring your vision to life.

If you are looking for professional custom board book printing services, contact us today to discuss your requirements and get a quote.